Email us now!

In various industries, the demand for sturdy and dependable packaging solutions continues to grow. Among the options available, plastic valve bags have become a popular choice for heavy-duty applications. These bags are designed to handle large quantities of bulk materials efficiently while providing protection during transport and storage. One of the common types used in such settings is the PP ton bags, which are well-known for their robustness and reliability.

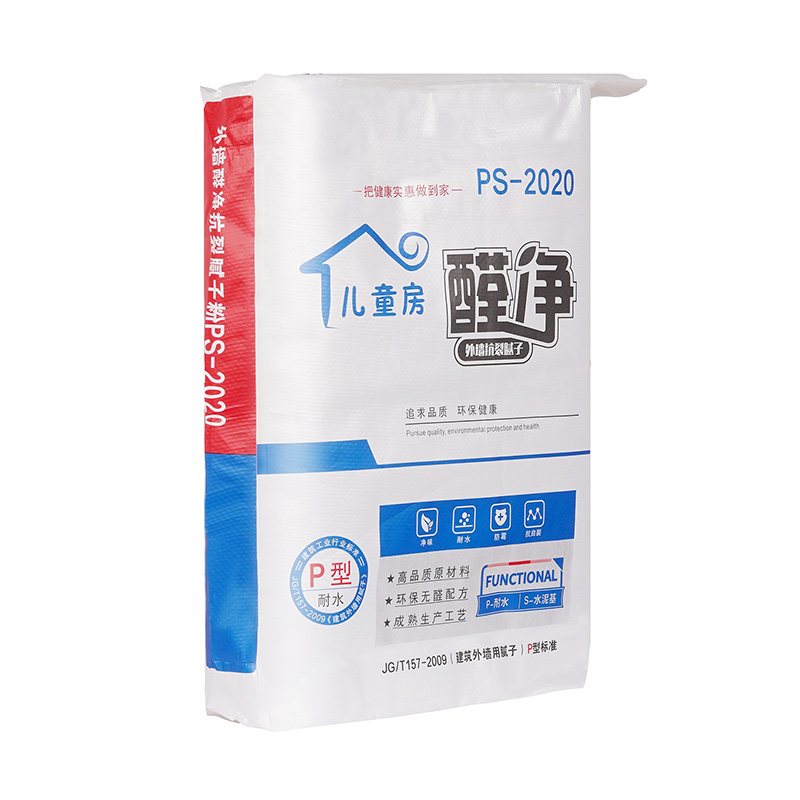

Plastic valve bags serve an important role in packaging bulk powders, granules, and other materials. Their design includes a built-in valve that allows for easy filling and secure sealing, less the risk of contamination or spillage. This feature makes plastic valve bags highly suitable for industries such as construction, agriculture, and chemicals, where maintaining product integrity is essential. The PP ton bags are often selected for similar purposes, offering additional strength for handling heavy loads without tearing or bursting.

The construction of plastic valve bags involves multiple layers of plastic film, which contributes to their durability and resistance to moisture. This helps protect the contents from environmental factors, ensuring the materials remain in good condition from the point of packaging to final use. PP ton bags, in particular, are made from woven polypropylene fabric, providing a balance of strength and flexibility. This material choice allows these bags to carry substantial weight while remaining lightweight and easy to handle.

One advantage of plastic valve bags is their compatibility with automated filling systems. The valve mechanism facilitates fast and efficient filling, reducing labor costs and improving overall productivity. For companies using PP ton bags, this feature is especially valuable when dealing with high-volume packaging needs. The design also supports reliable sealing after filling, which is critical for maintaining safety and quality standards in heavy-duty packaging.

Sustainability considerations have also influenced the development of plastic valve bags and PP ton bags. Manufacturers have focused on producing bags that can be recycled or reused where possible, helping reduce environmental impact. While plastic remains the primary material, efforts to improve recyclability and reduce waste contribute to more responsible packaging practices. This aspect is gaining attention as industries seek to balance performance requirements with environmental concerns.

The versatility of plastic valve bags extends across different sectors. They are commonly used for packaging cement, fertilizers, animal feed, and various chemical powders. The protective qualities of these bags make them suitable for long-distance shipping and storage in diverse conditions. Similarly, PP ton bags are frequently employed for heavy materials requiring secure containment. Their ability to maintain structural integrity under pressure makes them an effective solution in demanding environments.

When choosing packaging options for heavy-duty use, factors such as durability, ease of filling, and protection against contamination are key considerations. Plastic valve bags meet these needs effectively, offering a reliable option for bulk material packaging. The PP ton bags complement this by providing additional strength and capacity for larger loads. Together, these products contribute to efficient and secure packaging processes across many industries.

In conclusion, plastic valve bags provide dependable performance for heavy-duty packaging tasks. Their specialized design, combined with materials like woven polypropylene in PP ton bags, supports the safe and efficient handling of bulk goods. As packaging demands evolve, these bags remain practical choices that balance functionality with environmental considerations. Industries relying on bulk material packaging can benefit from the proven reliability and convenience offered by plastic valve bags and PP ton bags.

English

English русский

русский Español

Español عربى

عربى Türk

Türk