1. Product Description

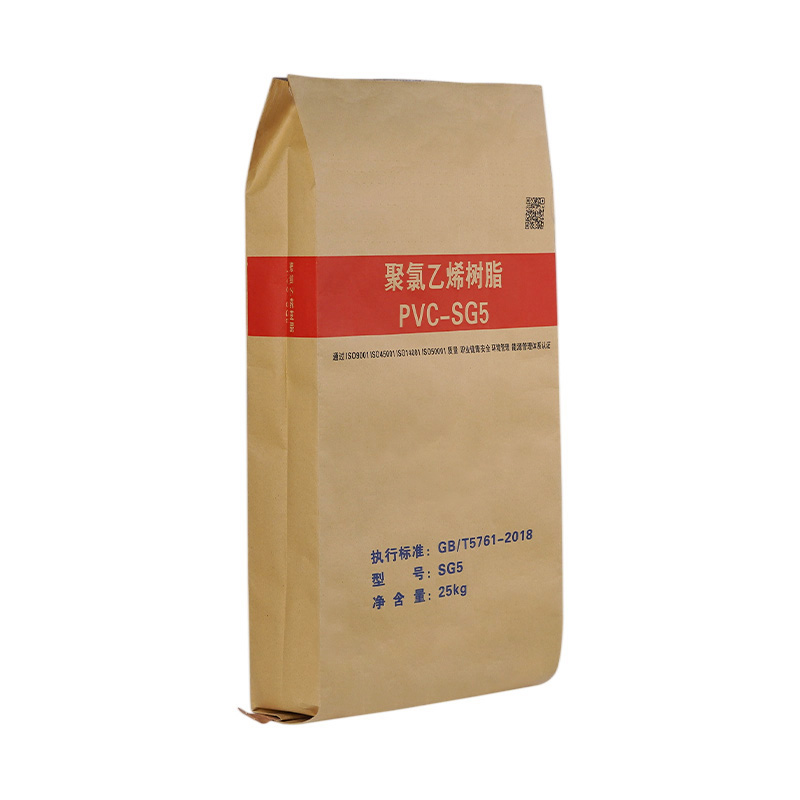

The Seam Bottom Kraft Paper Plastic Liner Bag is crafted from high-quality kraft paper on the outside and is lined with a plastic material on the inside. This design ensures that the bag offers both strength and resistance to moisture, making it an ideal packaging solution for products that require extra protection. The bag features a seamless bottom, which enhances its ability to hold heavy loads without the risk of splitting or leaking.

Kraft paper is a sustainable material that is recyclable and biodegradable, while the plastic liner adds an additional layer of protection, ensuring that the contents remain safe and secure. These bags come in various sizes and configurations, making them suitable for packaging a wide range of products, from dry food items like flour and sugar to agricultural seeds and chemical powders.

2. Key Features

Seam Bottom Construction:

The seam bottom design offers enhanced load-bearing strength, which prevents the bag from breaking or losing its shape when filled with heavy products. This feature is crucial for industries that require reliable and secure packaging, such as food packaging, agriculture, and chemicals.

Customizable Sizes and Configurations:

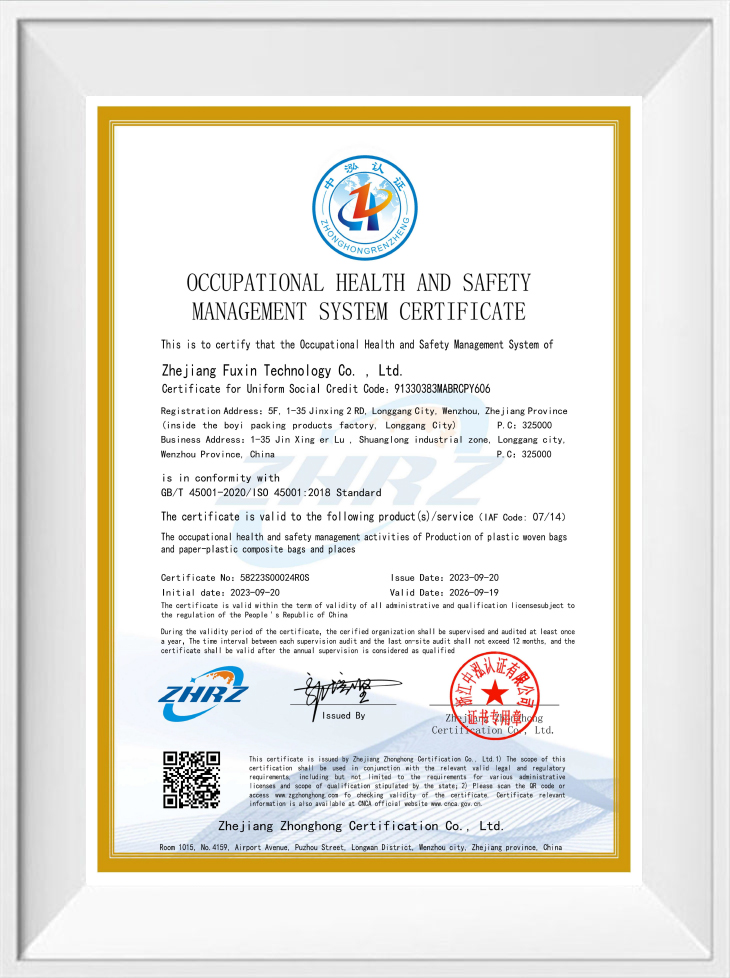

These bags can be manufactured in a variety of sizes to accommodate different product types and packaging needs. The flexibility in design makes them suitable for small consumer goods or large bulk materials. Additionally, companies can customize the bags with printed logos or branding for promotional purposes.

Plastic Liner for Added Protection:

The interior plastic lining provides an extra layer of defense against moisture, dust, and other environmental factors that could compromise the quality of the contents. This makes the bags ideal for products that need to be kept dry, such as flour, sugar, seeds, or chemicals.

3. Applications and Industries

The Seam Bottom Kraft Paper Plastic Liner Bag is widely used across various industries due to its versatility and reliability. Some of the common applications include:

Food Packaging:

These bags are commonly used in the food industry to package products such as flour, sugar, rice, powdered beverages, and other dry food items. The kraft paper exterior provides a natural, rustic look, while the plastic liner ensures that the food remains fresh and free from moisture.

Agriculture:

For agricultural applications, these bags are ideal for packaging seeds, fertilizers, and other agricultural products that require both strength and protection from the elements. The moisture-resistant liner ensures that the contents stay dry and safe during transportation and storage.

Industrial Packaging:

The bags are also used in the packaging of industrial materials such as chemicals, cement, and other powders. The strength of the seam bottom allows these bags to carry heavy loads without compromising their structural integrity.

English

English русский

русский Español

Español عربى

عربى Türk

Türk