Plastic Color Printing Woven Valve Bags: The Premium Packaging Solution for Modern Industry

In the demanding world of industrial packaging, efficiency, protection, and brand presence are paramount. Plastic Color Printing Woven Valve Bags stand at the intersection of these needs, offering a superior packaging solution designed specifically for dry flowable powders and granules across diverse industrial sectors. Combining exceptional durability with high-quality visual appeal, these bags are meticulously engineered to safeguard your product from external hazards, streamline your automated packaging operations, and elevate your brand visibility at every touchpoint throughout the supply chain—from production facilities to end-user warehouses.

Superior Construction & Key Features

Our bags are crafted from high-strength polypropylene (PP) or polyethylene (PE) woven fabric, a material selection that ensures excellent tensile strength and robust resistance to tearing, bursting, and abrasion, even in harsh handling and transit conditions. The defining feature is the precision-engineered valve sleeve, which is optimized for seamless integration with automated packaging lines, enabling clean, dust-free, and high-speed filling that significantly boosts production throughput. Once filled, the valve’s self-closing mechanism activates automatically, creating a secure and sift-proof seal that eliminates product leakage and maintains package integrity.

To ensure maximum product integrity, we offer integrated liners, typically made from food-grade or industrial-grade low-density polyethylene (LDPE) film, depending on your application requirements. This critical inner layer acts as a robust barrier against moisture, ambient contaminants, and fine-powder leakage, making the bags particularly ideal for hygroscopic, corrosive, or ultra-fine-powder materials that demand strict environmental isolation. Each bag is constructed with reinforced heat-sealed seams and a stable, flat base, enabling safe, secure stacking during both long-term storage and multi-modal transportation without the risk of toppling or damage.

Vibrant Branding & Customization

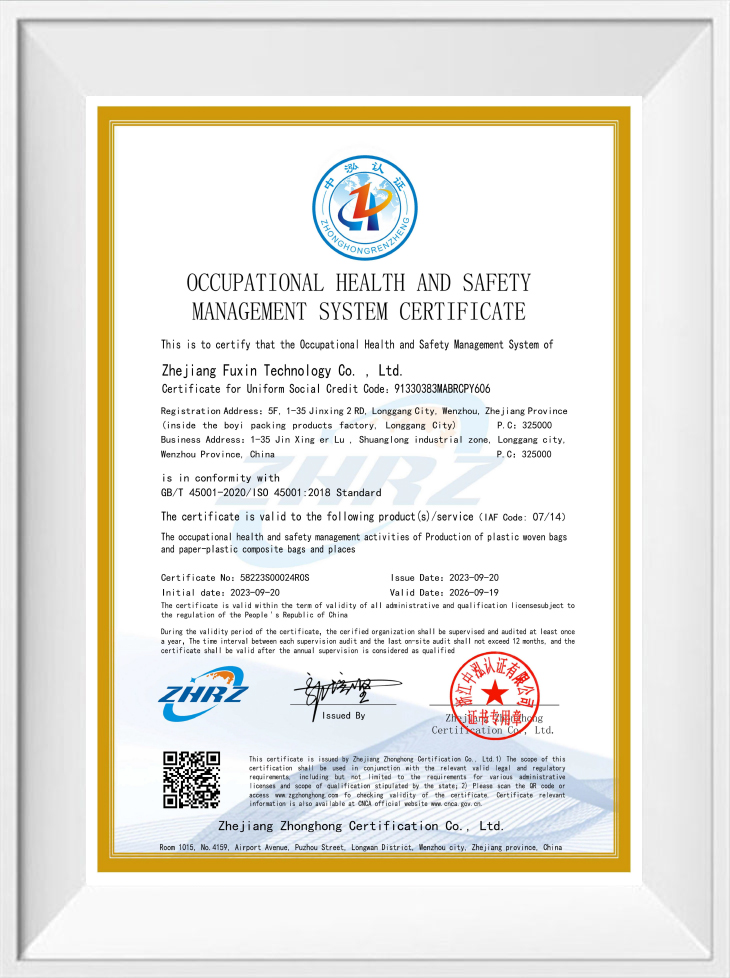

Move beyond generic, unmarked packaging that fails to showcase your brand. Our advanced multi-color flexographic printing technology, paired with high-quality, weather-resistant inks, transforms each bag into a powerful marketing asset. We produce sharp, vibrant, and abrasion-resistant prints that clearly display your logo, product specifications, batch numbers, handling instructions, and essential safety certifications (such as UN dangerous goods certifications for chemical products). This not only enhances professional brand recognition on crowded shelves and busy warehouse floors but also provides critical, easy-to-read information at the point of use, reducing operational errors. We offer complete end-to-end customization—from unique dimensions and capacity (ranging from standard 25kg sacks to 1-ton bulk bags) to specific printing designs, custom liner materials, and functional add-ons like UV protection for outdoor storage, anti-static properties for electronic component-related materials, or tear strips for easy opening.

Primary Applications

These versatile bags serve a wide range of industrial sectors, thanks to their customizable design and reliable performance:

1. Chemical & Fertilizer:

Ideal for plastic resins, compound fertilizers, organic fertilizers, pigments, dyes, and powdered chemicals, offering superior moisture resistance and durability to withstand chemical compatibility and harsh storage environments.

2. Building Materials:

The preferred choice for cement, gypsum, dry mix mortars, and construction sand, featuring exceptional strength and leak-proof performance to handle abrasive materials that can damage standard packaging.

3. Food & Agriculture:

Available in food-grade compliant materials (meeting FDA, EU 10/2011, and other international food safety standards) for flour, starch, sugar, animal feed, pet food, and grain products, ensuring product safety, freshness, and compliance with regulatory requirements.

4. Pharmaceutical & Fine Chemicals:

Providing clean, contamination-free, and tamper-evident packaging for sensitive materials such as pharmaceutical excipients, active pharmaceutical ingredients (APIs), and high-purity fine chemicals, where strict contamination control is essential.

Why Choose Our Valve Bags?

We are more than just a manufacturer; we are a trusted packaging partner dedicated to solving your unique operational challenges. Our focus is on delivering Total Cost of Efficiency—reducing your production line downtime caused by bag failures, minimizing costly product loss from leakage or contamination, and optimizing your filling and logistics operations through bags that are tailored to your equipment and supply chain needs.

English

English русский

русский Español

Español عربى

عربى Türk

Türk