1. Product Design and Structure:

The plastic laminated valve bag is composed of multiple layers, typically including a combination of woven fabric and a plastic laminate layer. The inner plastic layer ensures that the contents remain protected from environmental factors such as moisture, dirt, and contaminants.

a. Woven Polypropylene Fabric: The outer layer of the bag is typically made of woven polypropylene (PP) fabric, which is known for its high tensile strength and resistance to wear and tear. The woven fabric provides the bag with an added layer of protection against punctures, tears, and abrasions, making it ideal for handling heavy-duty materials.

b. Laminated Plastic Layer: The plastic laminate lining inside the bag offers a moisture barrier, ensuring that powders such as cement, putty, and other building materials remain dry and free from contamination. This laminated layer is often made from polyethylene or similar plastic material, providing a strong, flexible, and waterproof seal.

c. Valve Opening: The valve bag features a built-in valve opening that simplifies the filling process. The valve is typically located at the top of the bag, and once the bag is filled with powder, the valve automatically closes, eliminating the need for additional sealing. This ensures faster packaging times, reduces labor costs, and minimizes the risk of spillage.

2. Key Advantages:

a. Enhanced Product Protection: The combination of woven fabric and plastic laminate offers enhanced protection for the contents, particularly when it comes to powdery or granular substances. The moisture-resistant properties of the laminated plastic ensure that the material inside remains in ideal condition throughout its lifecycle, from production to end-user delivery.

b. Improved Durability and Strength: The woven polypropylene material provides the bags with exceptional tensile strength, making them highly durable and capable of withstanding rough handling during transport and storage. These bags are resistant to tearing, puncturing, and abrasion, ensuring that the contents remain securely contained.

c. Cost-Effective Packaging Solution: The plastic laminated valve bag is a cost-effective packaging solution due to its low material cost, ease of production, and efficiency of handling. The automated filling process, coupled with the self-sealing valve design, reduces labor costs and increases productivity in packaging operations.

3. Applications:

a. Cement and Concrete: Plastic laminated valve bags are widely used in the packaging of cement and concrete products. These materials are highly susceptible to moisture and environmental degradation, so the moisture-resistant properties of the laminated plastic ensure that the product remains dry and stable during transit and storage.

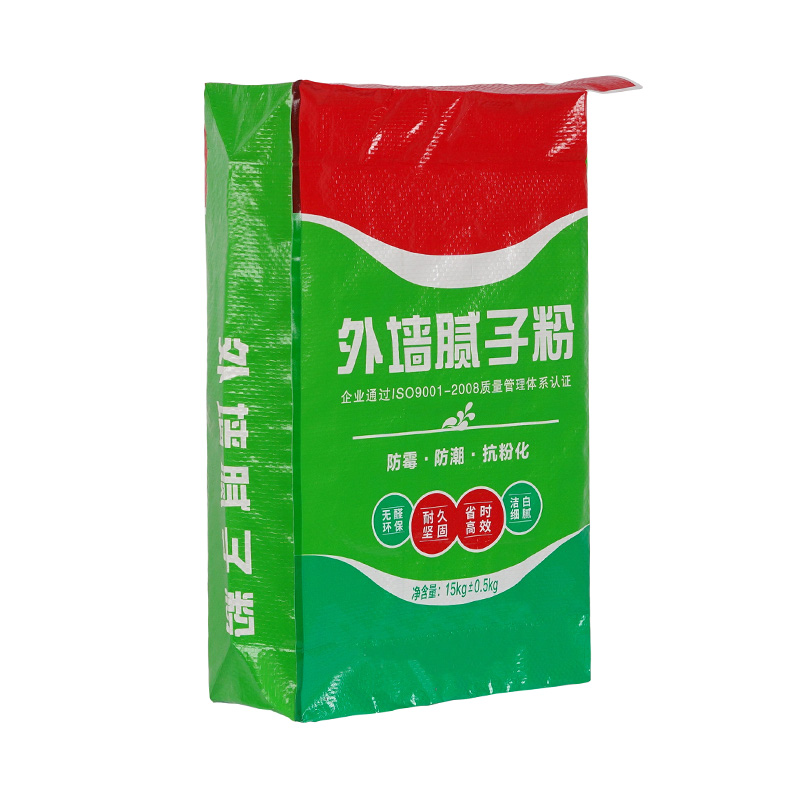

b. Putty and Plaster: Putty and plaster products are commonly packaged in plastic laminated valve bags to prevent clumping or hardening due to exposure to moisture. The bags' ability to protect the powder from moisture ensures that the product retains its quality and ease of use upon reaching the consumer.

c. Other Building Materials: In addition to cement, putty, and plaster, these bags are also suitable for a wide range of other dry powders and granular materials used in the building and construction industry. These include gypsum, lime, sand, and various types of mortar. The plastic laminated valve bag offers a versatile, cost-effective, and secure method of packaging these materials for both small-scale and industrial applications.

English

English русский

русский Español

Español عربى

عربى Türk

Türk